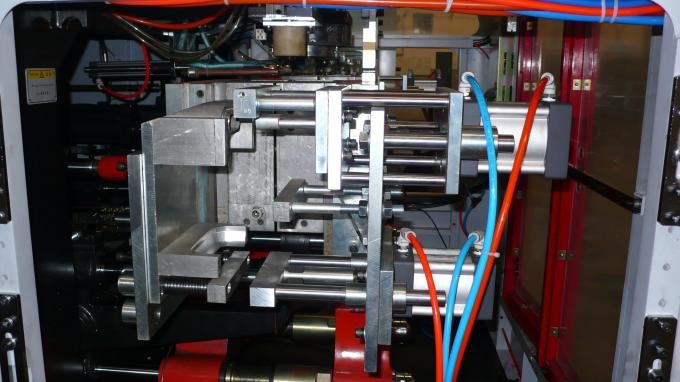

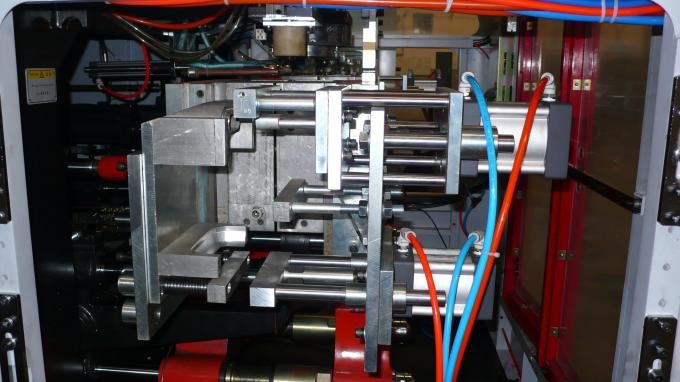

Customized extrusion blow molding machine single station with IML

system for milk bottle or yogurt bottle

Model number :MP70FS&IML

specification:

Brief introduction

MP70 is one of the most popular model for products below 5L

View strip optional

co-extrusion(multi-layer)optional

Double station or Single sation optional

Advantage:

1. Adopt four position leader structure and supporting grider design, it is

good at stability.

2. Carriage moving design adopts tie-bar and linear guide,heavy and

stong structure design make sure machine works more faster ,smooth

and stable in fast cycle.

3. Copper meatus connection between the platen and carriage

,self-detector distribute installed,make sure machine lubrication

system are in super good condition.

4. Adopt double proportional valve in hydraulic system, it is

high-efficiency in production and low vibration in pressure.

5. Special protection for the machine and people

Sensor in the operating door: if anybody enter the machine,the

electricity conneced with the machine will automatic cut down.

Temperature interlock system:When the material inside the barrel is

not reaching the setting temperature,the extrusion motor can never

start.that will help the screw and head of the machine.

6. Easy die head dis-assemble and assemble

7. Adopt and prefer to use seamless and stainless meatus in

hydraulic connection design from valve mainifoild to oil cylinder.

compare to pipes,it is more stable to avoid oil leakage.

Center distance introduction:

Double head standard Center distance:160mm (170,180,200mm as

option)

Thriple head standard center distance:120mm(100,120,125,130mm as

option)

Four head standard center distance:100mm(90mm as option)

Six head standard center distance:60,70mm

Mainly applicable field:

a) Pharmacy packing and cosmetic field:including madicin bottles,

eyedrop bottles,cosmetic bottles.

b) Auto parts: air-contidional pipes,oil tank,water tank,hollow

parts from the auto.

c) Food and beverage packing:beverage bottles(milk container,juice

bottles ,jar)

d) Oil and chemical field: petrol jars,oil barrel,painting buckets

other chemical packing and tray,cleanser bottles….

e) Toys: body of revise pens,gumwater bottles,sand beach

balls,hollow toys(including stationary toys ,collection jars and

big assembled slide ladder…..

f) Other applicable area:tool boxes,pesticide bottles,atomizer,bed

bords, desk bords,basketball bord

Machine specification:

| Specifications | | MP70 |

| Material | | PE,PP,(PVC,PA)OPTION |

| Max container capacity | L | 5 |

| Number of die | set | 1,2,3,4,6 |

| Machine Dimension(L×W×H) | M | 3.4×2.36×2.36 |

| Total weight | ton | 4.5 |

| Clamping force | kn | 70 |

| Platen opening stroks | mm | 180-480 |

| Stroke of mould board | mm | 300 |

| Platen size | mm | 340×420 |

| Max mould size(W×H) | mm | 400×420 |

| Mould thinkness | mm | 185-250 |

| Screw diameter | mm | 70 |

| Screw L/D ratio | L/D | 24 |

| Plasticising capacity | kg/h | 65 |

| Number of heating zone | zone | 3 |

| Extruder heating power | kw | 14.5 |

| Power of screw-bar machine | kw | 0.18 |

| Extruder driving power | kw | 18.5 |

| Number of heating zone | zone | 2 |

| Power of die heating | kw | 6.5 |

| Max die-pin diameter | mm | 130 |

| General power of machine | kw | 42.68 |

| Power of the electric motor of oil pump | kw | 9.5 |

| Air pressure | Mpa | 0.6-0.8 |

| Average energy consumption | kw | 23 |

| Using quantity of compression air | m3/min | 1.5 |

| Using quantity of cooling water | m3/min | 1.5-2.5

|

Defleshing system type:Push on top and bottom with air cooling

system.