Customized automatic blow moulding machine MP80FS-4 for 1L

lubrication oil container

Model number :MP80FS&IML

Brief introduction

Hydraulic system design extusion blow molding machine MP80 is

suitable for Producing Medium Size Bottles up to 10L of Various

Materials, and Equipped with Single Die Head, Double Die Heads,

Three Die Heads, Four Die Heads,Six Die heads.

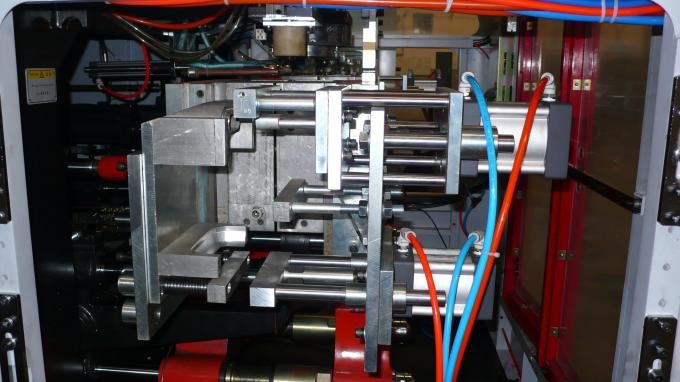

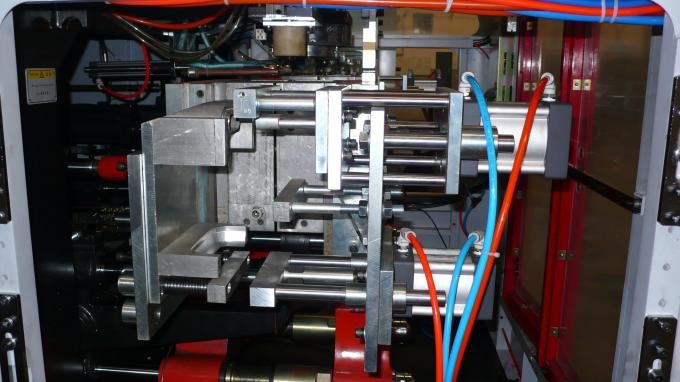

Adopt four leaders point support structure, it can accept heavy

moulds. With parison control system ,it is especially to make

bottles below 10 liter ,like toys, auto parts ....

Advantage:

1. Most important for a good EBM machine is the action system and

the extrusion system.

we'r using powerful hydraulic system design with imported valve and

pump for stable action

Adopt China famous brand Gearbox along with Delta extrusion motor

,make sure machine runs continiously,long life.

2. Heavy and stong structure,make sure machine works more faster

and stable.

3. Special protection for the machine and people

Sensor in the operating door: if anybody enter the machine,the

electricity conneced with the machine will automatic cut down.

Temperature interlock system:When the material inside the barrel is

not reaching the setting temperature,the extrusion motor can never

start.that will help the screw and head of the machine.

4. Special care for different countries.

we offer some special design for different countries,in order to

matching best performance.

5. Easy die head dis-assemble and assemble

6. Defleshing function included

1L lubrication oil container automatic blow moulding machine /

bottle blowing machine

Brief introduction

Smallest machine to produce 1L engine oil bottle with or without

view strip.

Double station,single head

Features :

- Suitable for making plastic products from 5ml up to 2L.

- Die Head is torpedo design with special flow channel for swift and

complete mergence of plastic material inside and to provide better

plasticized feature.

- Single view strip head

- Parison thickness micro control system is optional for product best

weight and quality control

- Die Mouth Extrusion Adjustment by 4-point adjustment,parison to be

straight and view strip width and position stable.

- High-melting Screw design by 38CrMoali material,Bimentallic aolly

material as optional for recycle material.

- electric-heated Hot Cutter for cutting the parison with micro

adjustment ,more accurate in blowing and reduce the scrap material

percentage.

- Blow Pin up down is driven by poweful hydraulic,micro adjustable to

center the to be exactly twist cup-off neck flash.

- Blow Pin Mandrel has the chill-water circulation up to the tip,fast

shaping the bottle neck.

- Linear carriage up down movement,more faster and stable

- center lubrication system with self-detector manifoild,ensure the

life of the mechnical parts

- heavy structure,make the machine works more faster without any

shake.

- defleshing optional to remove up and buttom scrap material

- scrap material convenyor is optional

- adopt festo exhausted valve,endrable and faster

- thick platen design to reduce the parting line of the products

- copper bush using for all the toggle parts,less friction heat comes

and longer life

- Air filter for water and oil,protect the pheumatic cylinder

- Techmation PLC ,easy operating with 8 language

optional:ENGLISH,SPANISH,CHINESE,FRANCE,RUSSIAN,TURKISH,PORTUGUESE

Machine specification:

| Parameters | MP80FS |

| Material | PE PP PVC PA… |

| Max container capacity | 10L |

| Number of die | 1,2,3,4,6 |

| Machine Dimension(LxWxH) | 3.7x4.7x2.9m |

| Total weight | 10.5ton |

| Clamping force | 200kN |

| Platen openning stokes | 240-560mm |

| Toggle stokes | 800mm |

| Max mould size(WxH) | 750x420mm |

| Screw diameter | 80mm |

| Screw L/D ratio | 24 L/D |

| (HDPE) Plasticizing capacity | 108kg/h |

| Screw heating zone | 4 zone |

| Screw heating power | 15.6kw |

| Screw fan power | 0.14kw |

| Extrusion motor power | 30kw |

| Die head heating zone | 12 zone |

| Power of die heating | 17kw |

| Total power of machine | 89kw |

| Power of oil pump motor | 31kw |

| Air pressure | 0.6-0.8 Mpa |

| Average energy consumption | 60kw |

| Consumption compression air | 1.5m³/min |

| Consumption cooling water | 60L/min |

Machine specification:

Defleshing system type:Push on top and bottom with air cooling

system.